| 產品簡介 | ||

|

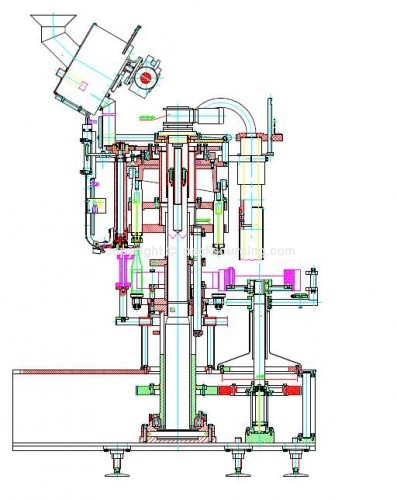

名稱︰CROWNER MACHINE 啤酒壓蓋機 | |

| 品牌︰未填 | ||

| 規格︰未填 | ||

| 價格︰/ | ||

|

Crown cap is transferred from Crowner machine to magnetic chute, control and drive system ensure the crown cap to be auto and seriate continued, magnetic chute adsorbs the Crowner to magnetic turn plate and when turn plate turns to material outlet, off- Crowner machine will lead the Crowner to material inlet track.

Due to almost no agitation and slippage for Crowner in chute, it reduces the wear and tear exactly. Crowner is through chute track of Crowner machine and cap, then comes to inlet Crowner plate; there is specific design gap meet crown cap of inlet Crowner plate face to chute direction, in the action of magnet, the capped core which in the center of capped head catch up the queen Crowner firmly, Crowner is dived and pressed by two roller of edge plate cam, Crowner head and one steel ball lock-up machine fit together, the lock-up machine ensures the crown cap side figuration and no affection of bottle height error and keep consistent, the bottle is encircled principle of capper machine and turned on the bottle tray, it complete pressing Crowner on the process bottle inlet to bottle outlet.

Untouchable switch is on the chute track to detect Crowner obstacle, if Crowner obstacle lasts a short time will the chute stop automatically.

Crowner airproof force is supported by the surface bearing of Crowner axis seat. To compensate uneven of bottle and breaking, bottle is made up by PU to amortize.

u Drive of Crowner:

The force of Drive Crowner comes from star axle gear which meshes to active drive bear of packing machine, the gear meshes to the gear of principle axis and ensures capping is process with packing synchronous.

u Adjustment of rise and fall for Crowner machine.

There is one group of surface bearing on the Principle axis of Crowner and it not only support the main body of Crowner machine but also connect the rise and fall screw, operate rise and fall motor and screw is turned by, then the achieve of rise and fall.

u Magnetic chute and Crowner transfer machine

To ensure the normal work of Crowner machine, it only uses Crowner of accurate specification and height, Crown cap is better reserved in dry room.

Chute and agitator of capper machine is installed separately, chute should be poured empty when completing operation, the crown cap comes into agitator from chute. Circumgyrate of Agitation wheel for agitator is drived by one motor which open and close is controlled by approach switch to avoid no damage of Crowner.

It has independent drive set for Magnetic agitator; Crowner was transferred to Crowner track by turn plate and magnet on inlet. Capper turns to right direction in the turn-over Crowner pipe and is used by next step.

If there is obstacle of capper track, capper is through one check remove switch and lead to one box, then capper slide from the box to agitate canister and whose amount is checked by photo electricity switch and controlled by machine.

Dear Sir:

This is Shirley from Hong Guan Machinery Co., LTD. Now I am writing for you to seek the opportunity to establish the business relations with your company.

We are one of the largest professional food machine manufacturing company in China and Taiwan. We have 40 years of business experience. We not only manufacture machinery, but also we provide professional planning, design, and support. Our quality of service and technological standards are stable and innovative.

Our company has not only one factory in Taiwan but we also have another producing line equipments in China Hefei and Zhangjiagang city. We specialized in producing line of drinks, beer ,orange, dairy and water equipments

We approach you today in the hope of establishing business relationships with you and expect, by your joint effects, to enlarge our business scope.

In order to acquaint you with our business lines, we really warmly welcome you for coming here and visiting our factory. We really feel honored when we cooperation with your large and famous company together.

Our products are as following:

Integrate systems of Liquid Processing

2,000 ~ 36,000 BPH / PET, Glass Bottle for Tea (Juice) Hot Filling Line. 2,000 ~ 48,000 BPH / PET, Glass Bottle for Carbonated Soft Drink Filling Line. 3,000 ~ 36,000 BPH / for Mineral Water Filling Line. 3,000 ~ 48,000 BPH / PET, Glass Bottle for Beer Filling Line. 2,000 ~ 30,000 BPH / Beverage and Aluminum Can Beer Filling Line. 2,000 ~ 18,000 BPH / for Concentrate liquid, (Sauce) Filling Line. A. Bottle Rinser B. Filling Machine C. High Viscosity Liquid Filler(Piston Filler) D. Conveyor System E. CIP System F. UHT (Tubular & Plate Type) Manufacturing of Single Equipment for Packaging Line A. Bottle Rinser Filler Capper(Monoblock) B. Automatic Filler, Aluminum Foil Capper & Sealer C. Case Packer Un Packer D. The whole packing facilities of mineral water E. The whole plant for juice Equipment F. The whole plant for Milk Equipment G. Packing Machine (Case Packer Shrink Wrapper & Wrapper Around) E. Crate Washer I. High & Low Level Bottle Depalletizer/Auto Palletizer J. Ice Cream Plant E-mail:johnchenboss@hotmail.com MSN:johnchenboss@hotmail.com SKYPE: johnchenboss |

||

| 該公司其它產品︰ 汽水 啤酒充填機 conveyor system 瓶輸送機 CROWNER MACHINE 啤酒壓蓋機 SHRINK SLEEVE LABELING MACHINE 套標機 Piston filler caapper 封蓋機 capper 均質機 啤酒及碳酸飲料灌裝包裝機 啤酒飲料生產設備 | ||

| 相關產品 |

| 聯系訊息 | |

| 所在地區︰ | 安徽省 - 合肥市 |

| 郵編/地址︰ |

230601/ 中國安徽省合肥市 經濟技術開發區錦繡大道206號

|

| 聯 絡 人︰ | John Chen |

| 電 話︰ | |

| 注冊時間︰ | 2009-08-14 19:33:58 |

| E-mail︰ | 點擊發送e-mail給對方 |

| 即時交流︰ | |

台灣包裝工業雜誌社(Taiwan Package)

儒學企業(股)公司(New Insight Publishing Ltd.) 版權共同所有

電話:886-2-28941823 信箱:viya@packsourcing.com

(本社為媒體並無銷售產品,請直接與本網會員廠商聯繫!感謝您!)

Copyright Notice © 2015 New Insight Publishing Ltd. All rights reserved.

Powered by Packsourcing & Taiwan Package

(本網建議您使用 IE8 瀏覽器觀看頁面,以免錯誤產生)